Ready to experience the difference?

Refrigerants for LNG Liquification

-

Products & Benefits

Our hydrocarbons are the world’s purest and include:

- R290 (Propane)

- R601a (Isopentane)

High-purity refrigerants:

- Improve plant safety

- Increase production rates, uptime

- Reduce energy costs

- Reduce environmental footprints

-

Why Does Purity Matter?

Contaminants Negatively Impact Safety, Productivity, Efficiency

Refrigerant contaminants can lead to gas leaks, equipment failure, and wasteful power consumption.

Contaminant Impact Water - Causes piping corrosion and possible lube oil breakdown in compressors.

- Freezes and expands, causing pipes to rupture.

- Generates ice shards that pass through the system, damaging pumps and seals.

Mercury - Causes metal to be brittle by forming aluminum amalgam, leading to stress fractures.

Ethane

(High-pressure gas)- Increases horsepower by placing unnecessary demand on the compressor drive and discharge coolers.

- Limits natural gas flow rate to offset the additional load.

- Causes a high-pressure trip at the HHP stage.

Butanes and Heavier - Requires higher refrigerant circulation to meet the targeted cooling temperature.

CO2 - Causes corrosion and freeze-ups in the presence of moisture.

Other impurities

(neopentane, etc.)- Causes freeze-ups in the Mixed Refrigerants (MR) loop.

-

Electrical Cost Savings

LNG plants using high-purity refrigerants realize substantial cost savings.

Average Electric Savings* Low-Purity vs. Diversified CPC High-Purity Refrigerant $1.26 Million savings per year, per train * LNG plant utilizing C3MR process and a 100K horsepower compressor; producing 5 Million tons annually with an electricity cost of $0.06 / kilowatt hour

-

Compressor Performance

There is a direct correlation between refrigerant purity and compressor performance. The diagram below is a typical high-efficiency centrifugal compressor performance curve. With impurities like ethane, CO2, butanes, etc., the polytropic head will trend high toward the surge limit, which is not desirable.

A Sustainable Solution

By using high-purity refrigerants, LNG plants minimize process disruptions and avoid flaring ethane and other lighter components during the HHP stage. These high-purity hydrocarbon refrigerants are:

- Zero ODP

- Low GWP

- Non-toxic

-

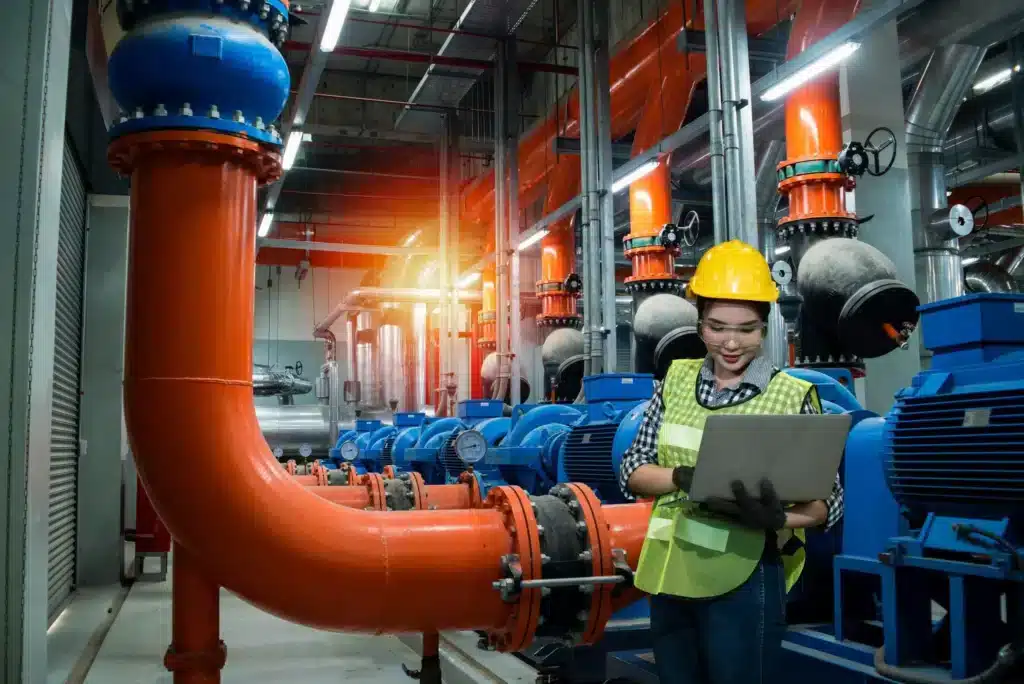

Purity from Production to Delivery

Our high-purity refrigerants are produced at and distributed from Diversified CPC plants throughout the United States. They are transported via dedicated fleets that are designed and operated to maintain product purity levels. We offer:

- A Certificate of Analysis with every product shipment

- Exceptional on-time delivery through a dedicated fleet

- Bulk and cylinder options

Key Takeaways

High Purity

Our high-purity hydrocarbon refrigerants are engineered to optimize your operational efficiency.

Sustainable

Hydrocarbon refrigerants are a sustainable solution. They have zero ODP, a low GWP, and are non-toxic.

Qualified

We manufacture UL-Classified refrigerants. Our hydrocarbon refrigerants also meet or exceed AHRI Standard 700.

Related Solutions

Our high-purity products are

leveraged across an array of

industries.

We Are Passionate About Results

Customers rave about our service and leading brands trust us to provide high- purity solutions for their products. We have been exceeding customer expectations since 1964 and we’ve only just begun.